How Field Work Can Be Faster

At my old Power Company, we used to have a group of field workers called “inspectors.” The term was a bit misleading, because this group didn’t actually “inspect” any assets. So what did they do?

After a designer created a work order — such as a new customer connection, an underground installation, a pole extension or relocation, and so on — the inspector would visit the job site. Their job was to match the as-is asset information from the designer’s work order to what was actually in the field. For instance, an underground inspector would crawl into a manhole and then verify the conduit that had been selected for a new cable was, in fact, empty. Likewise, an overhead inspector would check the validity of the equipment installed on a pole.

Since there were only a handful of inspectors, the work orders would just have to wait until the verifications were complete. If the inspectors found a discrepancy, which they usually did, the designers would have to redesign the entire work order. Then the inspectors would return to the job site and re-validate the design.

No big deal, right? Took a little extra time. So, what?

Yes, big deal.

The Cost of Not Being Able to Trust the Data on Your Map

This process was very costly in terms of both time and operational expenses. It meant that for every work order, there would be multiple field visits. First, the designers would often visit the site. Then there was the additional inspector field visit, or visits. Plus, if the inspectors found a discrepancy in the design, they had to notify the GIS department too. (Sometimes they did, sometimes they didn’t.) This bogged down the work order time line.

Customers would just have to wait to get their service. Developers would have to hold their breath as they watched their project timelines slip.

In all of this, there was an unspoken question.

Why didn’t the designers simply refer to their GIS for the as-is condition of field assets? Why did they have to visit the site at all?

Simple. They didn’t trust the data on their maps.

How Did the Data on Our Maps Become Untrustworthy?

At the Power Company, as with many utilities, building the GIS had meant digitizing the asset information from their old paper maps. If the old paper maps were inaccurate, then so would be the digitized GIS data. In fact, in a study Esri conducted several years ago about smart-grid preparation, only 15% of the 200 utilities that responded said they had had “high confidence” in their GIS data. (Read the full study, “Is Your GIS Smart Grid Ready?” here.) Many utilities had yet to finish converting their paper maps to GIS.

Among those that had digitized, what were the most common information gaps?

- Land Information – They were using old inaccurate base maps

- Asset Locations — They didn’t have the location of assets, such as distributed energy facilities and substations

- Information About Secondary Systems — As more people install solar panels and electric-vehicle chargers, the condition and information about the low voltage areas (e.g., secondary mains and services, electrical substations) is becoming critical

- System Details — Information about transmission and sub-transmission systems was lacking

It’s no wonder utilities rely on inspectors to verify asset information in the field. The asset data is suffering from a cycle of missing or inaccurate inputs.

It’s much cheaper to send an inspector to the job site before the work begins, than to send a construction crew to go out and work around inaccuracies. Imagine the cost of eliminating the inspector’s job …

The construction crew — complete with line trucks, diggers and police details — would often find as-is asset information on the design wrong. And then what? Would they leave the job site? Of course not.

What actually happens is the construction crews improvise around design inaccuracies. They work around the errors. Afterwards, the crew supervisors report the deviation from the work-order design in the form of a field mark-up (a sketch or redline on the design).

Or would they, really?

What if the supervisor is too busy? What if the field sketches got lost? What if the crew simply didn’t bother to report deviations from design? What if there was a storm brewing and they had to rush to another job?

The reality is that bad designs, based on bad data, creates a vicious cycle of more bad data. Bad data begets worse data.

Moving from a Digital Mutant to a Digital Twin: Improving GIS Accuracy

But it doesn’t have to be this way. In fact, the increasing capabilities of the GIS to serve as a digital twin is creating an opportunity for, and desire among, many utilities to re-evaluate and improve the quality of their GIS data. And many utilities are taking advantage of this opportunity.

Why? They want to take advantage of the “digital twin.”

The idea behind a utility GIS is, after all, to create a digital twin. What’s that? A digital twin is simply the virtual, visual, and geospatial representation of your electric grid (or other infrastructure network). Digital twins are capable of generating huge efficiencies in utility operations, streamlining asset management, and optimizing workflows. They also set you up to take advantage of future technologies that require high-quality data, such as augmented reality.

The problem is, many utilities don’t have a digital twin. And the problem isn’t because of the technology. It’s because of the untrustworthy data.

Most utilities are still working off the inaccurate paper-map digitizations and field records. Without more accurate, complete and up-to-date data about their assets, the GIS can never serve as a true digital twin.

Instead, it becomes a digital mutant.

How Do You Turn Your Digital Mutant into a Digital Twin?

How do you break the cycle? How do you turn your digital mutant into a digital twin that can you can trust? One that eliminates the costly and time-consuming inspector field trips and sets you up for the future?

As more utilities acknowledge the value of improving data quality, we’ve seen a rise in requests for help getting there. To that end, here are seven tips we suggest performing immediately to improve GIS accuracy and turn your geodatabase into a true digital twin:

- Cost Analysis: First, recognize the problem — the costs and customer impacts associated with bad data. If you had a real digital twin, you would never need to go into the field to verify designs, for instance.

- Field Mobility Solutions: A number of ArcGIS-based field mobility solutions, such as ArcGIS Collector and ArcGIS Survey123, exist to short-circuit the long and hazardous journey of transmitting data from the field to the office. As you adopt a proven mobile workflow, the quality of your data gets better for all the data collected going forward. But you still have to address legacy data …

- Asset Inspections & Corrections: Employ a field mobility solution for inspections and field-data corrections to improve accuracy of legacy data. Alert literally everyone who is working in the field to report deviations, and empower them to do so with an one of the many available ArcGIS-based mobility solutions.

- Deploy High-Accuracy Mobile Solutions: High-accuracy technology from companies such as Eos Positioning Systems allow your field crews to easily access submeter and centimeter location in the field, and collect this data on Esri mobile apps. We are seeing a huge uptick in even small utilities being able to affordably and quickly update deviations from the GIS and reality thanks to high-accuracy mobile workflows.

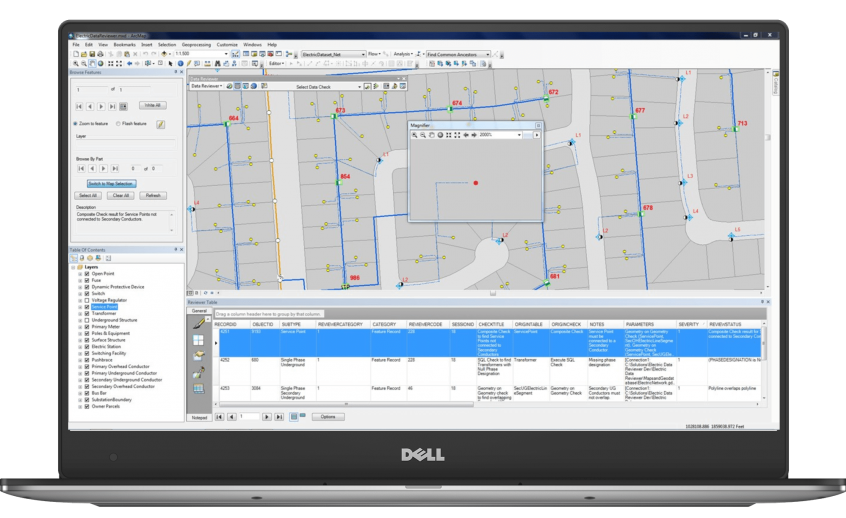

- Quality Control & Validation: Impose additional processes for quality control and data validation in your editing workflows. Esri’s new Utility Network Management Extension for ArcGIS provides enhanced quality-control mechanisms to help you.

- Data Audits: ArcGIS has a variety of spatial analysis tools to help you understand where gaps in data quality exist. You can easily identify areas for improvement, and then create dashboards to measure improvements over time in quality, accuracy and timeliness.

- Capture Everything & Close the Gaps: Your GIS can’t be a “system of record” or “single source of truth” if the data is missing or incorrect. Capture as much data about your grid as accurately as possible. This is a great opportunity to leverage the unprecedented advancements in mobile capabilities of Esri mobile apps and high-accuracy technology like external Eos GNSS receivers.

Final Thoughts on Creating Your Digital Twin

Moving from a digital mutant to a digital twin requires a commitment to data quality. Thankfully, utilities have a strong culture of asset quality. They are already familiar with measuring reliability, maintenance history, and construction spending as well as benchmarking.

Now, data quality is just as important.

Moving from a digital mutant to a digital twin will also require a commitment from senior management. Remember, and reiterate, that transforming data quality will lower costs, shorten job-cycle times, create safer working environments and improve efficiency. Moreover, it sets the stage for your utility to enter the realm of ROI-driven emerging technologies such as 3D GIS, augmented reality, and more.

To learn more about utility GIS click here.

About Your Author:

Bill Meehan

Bill Meehan, P.E., heads the worldwide utility industry solutions practice for Esri. Author of Enhancing Electric Utility Performance with GIS; Modeling Electric Distribution Performance with GIS; Empowering Electric and Gas Utilities; Power System Analysis by Digital Computer, and numerous papers and articles. Bill has lectured extensively and taught courses at Northeastern University and the University of Massachusetts. Bill is a registered professional engineer.