As the Corrosion Supervisor at CountryMark, David Wiggins takes pride in extending the life of essential infrastructure. By identifying and mitigating corrosion, he helps keep systems safe, reliable, and operational for years to come.

David and his team use ArcGIS® Survey123 with the Eos Arrow 100® receiver from Eos Positioning Systems® to collect accurate field data for pipeline condition monitoring. Just how many elements are involved with monitoring pipeline health that require high accuracy? According to David, he uses the technologies to track atmospheric exposures, measure pipe depths, discover unknown assets, and view reports of various field data in real-time from the office. Having high accuracy in all of this streamlines operations and enhances team collaboration.

Keep reading to discover how David uses GNSS and GIS to keep CountryMark’s systems reliable for years to come.

1. Why are you passionate about your job?

Corrosion can cause significant damage to infrastructure and pipelines, and this potentially leads to hazardous situations. As the Corrosion Supervisor at CountryMark, I play a key role in preventing these issues and ensuring that critical systems remain safe, functional, and reliable. Corrosion control is a crucial part of asset management, and preventing corrosion prolongs the life of expensive infrastructure and equipment. I feel a sense of pride in contributing to the longevity of vital assets. I also find the challenge of identifying corrosion problems, diagnosing causes, and finding effective treatments rewarding. The field of corrosion is always evolving with new materials, techniques, and technologies. This constant change keeps the work interesting and engaging, with opportunities to learn and apply new knowledge.

2. How did you first find out about Eos Positioning Systems’ GNSS products?

I heard about Eos products in 2019 when our GIS Specialist Erin Mara introduced the right-of-way (ROW) team to the Arrow 100 GNSS receiver. A year later, in 2020, the corrosion team was using the Arrow 100 GNSS receivers as well.

3. What do you use Eos GNSS products for?

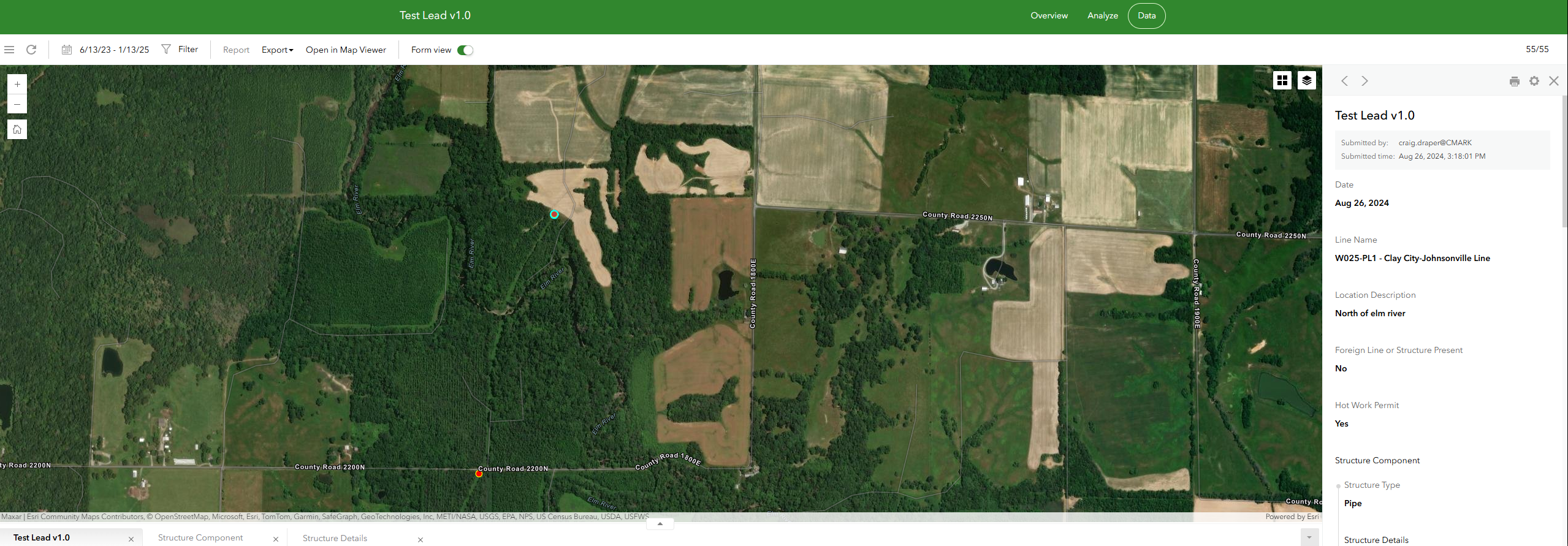

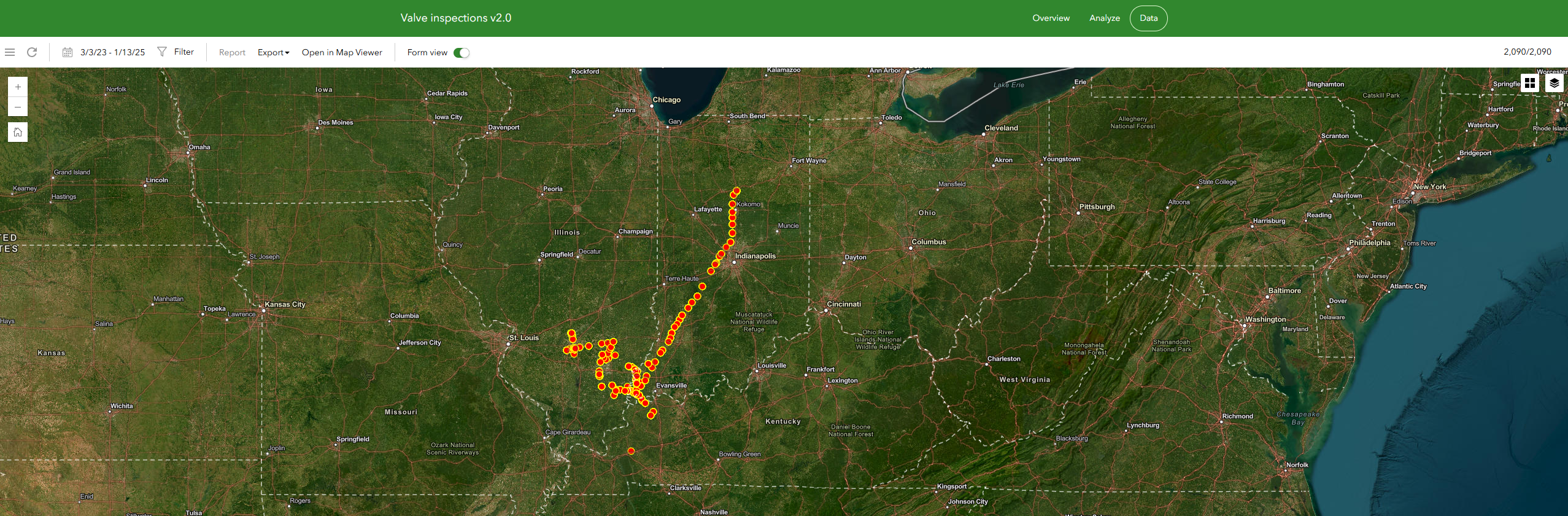

Currently we use the Arrow 100 GNSS receiver with our iPad® and close interval survey (CIS) equipment (specialized gear for detecting pipeline corrosion). We also use the receiver to obtain accurate locations for our field data and reports. The data include CountryMark assets, foreign crossings and assets, valve inspections, atmospheric exposures, pipe depths, low and high readings, anomaly dig locations, and installed isolation devices.

4. Do you have a favorite experience or memory from your projects with Eos hardware?

Yes, mostly an overall experience; when my team is working long distances from the office, we can depend on the Arrow to work when our team gets in the field. We also like the fact that we can see information in real time. Most of the time, I have our reports collected and added to a work order before my team is back to the office.

The Arrow being so easy to use has helped all the teams buy into using newer technologies.

5. Do you have a favorite feature of Eos GNSS receivers?

The Arrow being so easy to use has helped all the teams buy into using newer technologies. It’s also nice that there are multiple ways to mount and carry the units; depending on the job, we have used the backpack, iPad and pole mounts. I also like that the receivers are very easy to operate and sync to. A new user can be brought up to speed quickly and with very little technical skill needed.